high-sise building at Stockholm

Göran Ervin Schömer

Architect

Abstract of the Report of Building Research

ISSN 1400-2930

THE THEORY OF THE PRODUCTION OF ARCHITECTURAL SPACE

THE RELATIONSHIP BETWEEN THE SIZE OF THE SPACE-ENCLOSING STRUCTURES, WORKING HOURS AND PRODUCTION COSTS.

THE ECONOMY OF THE RODUCTION OF ARCHITECTURAL SPACE.

CRITICISM OF THE GLOBAL BUILDING METHODS.

ERVIN GÖRAN SCHÖMER Ph.D; Structural Engineering, Structural Mechanics, Prefabricated Building Systems

Member of the: Association of Swedish City Architects and Planners, The National Association of Swedish Architects, Association of Hungarian Architects

Office: Sweden 18132 Lidingö Torsvägen 26;

Senior Researcher of the Royal Institute of Technology, 100 44 Stockholm, Department of Architecture and Townplanning.

Institute of Building Structure and Structural Engineering.

Kungliga Tekniska Högskolan, Stockholm

The Royal Institute of Technology

Author: ERVIN GÖRAN SCHÖMER

THE THEORY FOR FUTURE BUILDING TECHNOLOGIES: THE THEORY OF THE PRODUCTION OF ARCHITECTURAL SPACE.

For a society as a whole it is important to accomplish the necessary space supply with a minimum of investments, i. e. to produce interior shelter space (rooms for living and working) at the lowest possible cost. At the same time the high quality of the products must be guaranteed.

Architecture is the art of space based on certain physical and technical principles and the circumstances of the actual project. A room cannot exist unless defined by structures which enclose space. Space is produced/determined by certain physical units. Even a subtle demarcation of space is based on other, factual, spatial enclosures. The history of architecture follows the development of the constructional capacity of mankind. The discovery of the beam, arch, vault, reinforced concrete, made possible various architectural epochs. As well other secondary changes takes place in architecture. They are type of form and idea decorations, ornaments. They are variations of the look of the primary elements and the created spaces The really good architecture is originated, when the primary and secondary elements of architecture are in harmony with each other.

Studying building operations from historic point of view, it can be observed that deliberate production of architectural space for man's sojourn on earth first took place in prehistoric times; it is contemporary with homo Sapiens. that building operations are site-specific, and have always meant that people erect houses, works, towns on a given site. Initially people built their houses of rock or wood found near the site; later, in our own days of brick, reinforced- concrete members, etc.

Since building operations have been carried out by mankind for millions of years, terms having to do with building have to come to be associated with building, assembling together materials of the site for a building. Modern man, influenced by heredity and environment, can hardly imagine constructing a building in any other way, than producing small or medium sized components, and putting together at the site. This is a fundamental reason why we are still building so irrationally around the world.

NEED OF HOUSING

The population of the world, according to the UN year 2000 rise to 6.1.10e9 (billion) 4.8.10e9 live in the developing- and 1,3 billions in the industrialised countries. Our mother earth can, according to the same source of information, support 13.0.10e9 human beings, considering unchanged type of food production, storage and distribution. Consequently, the need for indoor living space on world will be doubled as from today. That implies, among others that at the beginning of the twine-first century will be a need housing for one billion peoples. Year 1992 the GNP on earth was 21.6.10e.12 (thousand of billions) USD.

The GNP of the world increased during the 1980-s and 90-s 2,0 - 2,5 percentage per year. I- countries had 85%, d- countries 15% of the GNP of the world. The investments in building industry in the i- countries used to be around 60% of the total investments. Building investments which belong to this report treat 2/3 part of that. The investments on the whole world are equivalent to the GNP of the Germany and Spain. Investments in building on the globe as large as the GNP of Germany (approx. 9- 10%). In this article is discussed how can we save in building on earth as much as the whole GNP of Sweden and plus eventually even the GNP of Denmark. The GNP of Sweden is approx. 1.0% of the world.

United Nations by economic-demographically studies recognised, at year 2000, least 55% of the inhabitants of the earth will live in large metropolis. This metropolis are developing around the world as well on the northern par, as o the southern part: mainly between the 15-th and 35-th latitudes. Topic such areas follows: f. e. Cairo, New Delphi, Calcutta, Beijing, Shag Hi, Bangkok, Mexico City, Rio de Janeiro, Buenos Aires. The metropolis of the i- countries are laying around the 40-th latitude: f e New-York- Washington DC, Saar-Köln, Paris, London, Istanbul, Moscow, Tokyo-Kyoto. But we can recognise the highest increase of population is between the 35-th and 15-th latitude. A topic such metropolis has an area of 10e5 (hundred thousand) square kilometres. At the end of this century shall live there 20- 60.16e6 (millions) people in a such area. That means 200- 600 persons/sq. km. (To be compared Stockholm Region has today 120 persons/sqkm, Holland 400).

At the beginning of the next century UN has estimated the need of housing for 10e9 (billion) people. To this sum we have to add the need of acceptable working spaces, which can be calculated more as 10e8 room units. (One rooms unit in housing is ca 20-25 sqm, in working rooms 30 sqm). This need consists by rooms and groups of rooms of the size of 10 - 100 cubic meters.

BUT HOW PRODUCES THIS ROOM UNITS? As our heritage gives us impulses, dominating part of these rooms are produced by traditional matter. "Stones laid down on stones", "brick by brick".

FOR THE ENTIERLY SOCIETY IT IS VERY IMPORTANT, THAT THE NEED OF THE ROOMS IS COMPLEETED BY MINIMAL ECONOMIC SUPPLY

After the second world war different kinds of prefabricated building systems are developed. The traditional methods to build monoliths are changing to building systems which more ore less use prefabricated elements. Today we have about 200- 300 type of frequently used prefabricated systems (see a. o. System Buildings Schmid-Testa, Industrialised Buildings Building Research Institute of England).

ANALYSE OF THE BUILDING SYSTEMS OF TODAY

We can examine and control the building systems of today by analysing the actual building for housing, because the shape of topic rooms for housing are quite similar. Some relationship exists at the production of working places, f. e. offices, service, rooms, but this type of analysis is complicated because of this type of building varies much in their shape.

In housing construction we find the following typical building systems.

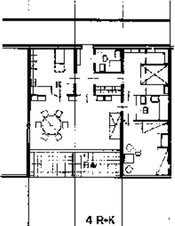

Conventional on-site system; casting the concrete slab on form, casting or brick on brick making the walls, partly pre produced mechanical equipment's, painted kitchen equipment's; boards, and working benches, carpenter works, rooms are painted at the site; f. e. industrialised Concrete (allbetong) system, picture 1, or wooden balloon system, picture 2.

Picture 1

Picture 2

Small size space enclosing element system, 600 mm width of the elements in concrete, pre produced carpentry. Painting at the site; f. e. lightweight concrete system, picture 3. One or two story high wooden housing during the 1960-es 70-es, not any longer in production. Area of the elements up to 5,0 sqm (small element). "Area of the element" means elements to create architectural space.

Picture 3

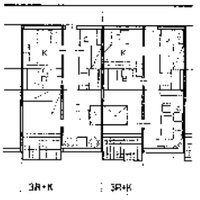

Prefabricated elements in size like a part of the room or the whole wall of the room. The level of prefabrication is similar to small element system. Wooden construction Anebyhus, picture 4, area:5,0- 12,0 sqm. House of concrete produced by Camus system, picture 5, area:12,0-25,0 sqm, a variation of that; Ohlsson & Skarne system, which has been developed to Skanska Prefab picture 6. The area of the elements between 12,0-25,0 sqm (middle sized elements). L- element system, picture 7. The topic elements size is a. 20,0 sqm.

Picture 4

Picture 5

U- formed elements combined with room sized plates on each other, f. e. Techcrete; high level of prefabrication, like system s. e., picture 8. The area of the elements can be 60,0 sqm (does not exist in wooden construction).

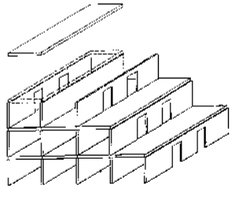

U- Box unit type building system, elements by prefabricated room sized or part of the room sized element which are placed on each other or side by side. Modulenthus in wooden construction, picture 9. ELCON-system in concrete, picture 10. Heavy concrete system in the previous Soviet Union, picture 11. Finish like s. e. The area of the elements up to 140,0 sqm.

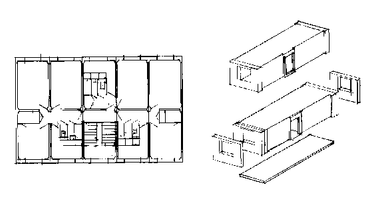

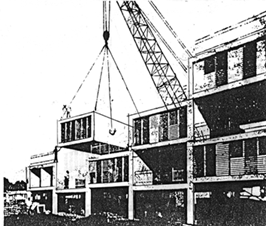

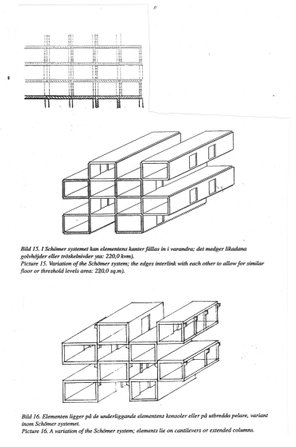

V- Box units placed one upon the other vertically in a chessboard pattern; Shelley system, picture 12. According to the Shelley system placed the box units upon each on others slab, that results every second slab must be completed, by casting more concrete on the slab, or building up the floor f. e. by wooden construction: to create the same floor level in one flat. According to the Schömer system the box units sunk in each other by especially formed edges of the elements, picture 13, alternative the elements lie on cantilevers, picture 14, or on extended columns, picture 15. Finish like s. e. The area of the elements is up to 220,0 sqm. (Vertically in chessboard pattern.)

Picture 10

Picture 11

Picture 12

Picture 13 - section and prodution of elements

High-rise building at Stockholm

The mobile home (comparing the possibilities), picture 16. Finish, ready to live in. The area of the elements varies between 70,0 - 250,0 sqm., produced by plywood on steel framework, insulated well by foams. Referents object.

The other systems on the market are the combination of the mentioned systems. Large building project or complex produces by the combination of different building systems.

To compare the characteristic building systems we have introduce sudden simplifications:

We compare the classified systems made of similar materials (concrete to concrete, wooden to wooden).

We presuppose that the building systems produce buildings by the same efficiently in the factories as at the building site.

The amortisation of the cost of the factories and building equipment's can be arranged by a sufficient large volume of production, normally minimum 40 - 60% of the maximal production volume. Heavy system needs higher productions volume (approx. 3000-4000 dwellings / year) as light system. We presuppose that the different building systems produce good, acceptable standard of rooms.

Comparing of the different building systems: the characteristic building system of concrete marks on the x- axis of the orthogonal diagram. We find from left to right, by the enlarging of the space function of the elements the total working time for production of rooms reduces from 100% for on-site method, to 30% for the mobile home, picture 17. According to the same type of observation; the enlarging space creating function of the elements, we find the working hours changing in the factory/on the site from 30/70% to 82/18% for the mobile home, picture 18. The statistical dates belong to the 1970-s.

The above mentioned empirical, statistic material is collected by the Swedish construction companies Skånska Cement, SIAB/NCC. But the really production costs: (cost in the factory plus at the site) are secrets of the business. The prize follows as we know the developments of the market. Therefore the total production costs has been analysed by an indirect method. Within a sudden time period amortised purchased sum has been compared with a (large) productions volume. (Skånska Cements buy of the Ohsson & Skarne system). For concrete building systems, the total production costs analyses as the function of the enlarging of space functions of the elements.

Picture 17

Picture 18

We find on picture 19; the total costs decrease from 100% on site method, to 55% for the mobile home. (During the 1990-s the costs of the mobile homes fall down to 40%.)

The decreasing of the total working hours and building cost for wooden structures are similar to the concrete structures, but between balloon frame and small element system we find a larger step as between on-site and small element system in concrete (Swedish experiences).

Picture 19

In the theoretical point of view the above written is evident. To build up a house by one cubic centimetre large elements we have to spend of more time as to build up the same house by brickwork. At the same time as the space creating function of the element increases, larger part of the room is produces in factory, that results more control of the total costs.

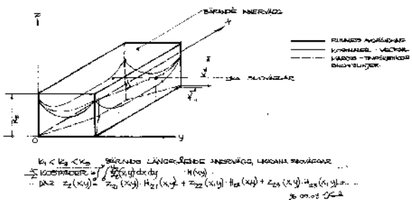

The prize variation depending on the location of the building site becomes less part, and loses its importance of the total costs. The surfaces of the encasing structure of the room (floor, walls, roof) corresponds a part of the space of the room, which is enclosed by, and the necessary working hours and costs to produce the room. We can imagine like a picture this relationship, as three dimensional breaching lines in the room, which follows Marcus'- Timoshenko's breaking lines on the plane. That is valid in normal sized rooms in housing or office building. On picture 20 we find the theoretical relationship of the costs and mathematics of the production of room, which is located at the outside wall.

Picture 20

There is a relationship between the size of the enclosing structures of the room (floor, walls, roof: measured in two dimensions) and for the needed working hours and production costs for building the room (measured: in three dimensions).

The numerical relationship between the size of the enclosing elements of the room, working hours and costs are not known in details. However some signs interpret:

For production of room needed working hours (T) and costs (C) are equivalent to the quadrate root of the enclosing elements total circumference (CF). T1:T2 = c1.C1:C2 = c2.quadrateroot(CF1:CF2). There c1 and c2 are constants.

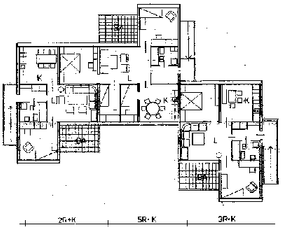

INDUSTRIALISED PREFABRICATION IS CHANGING REMARKABLE

The size of the elements are growing continuously. Despite we have build in Sweden much more dwellings during the 1970-s as we do it in the 1990-s, today we are building by accurate larger size of elements as before. At the middle of the 1970-s we have produced a normal two bedrooms apartment by 35-36 pieces of elements, now we do it by 25-26 pieces. To look forward, the author of this paper has projected a normal two bedrooms apartment by 12 pieces of elements.

The volume unit system increases during the 1970-s and 80-s. The volume unit system take over more and more market from the on-site, balloon type of housing in one- and two-storey wooden building constructions. The units used to get according to the allowed transport profile following dimensions: maximal width 3.6 m, length 12-18 m (in Sweden 24 m), height 3.5 m. For light element systems the practical transport distance is growing quickly. Up to 1500 km can be light (wooden) elements transported.

Elements for concrete systems can be transported up to 250 km.

In the USA during five years in the 1980-s the production of the wooden, volume box based housing has doubled. But the largest part of the small houses in one- two or three stories are produced still in large elements as plates and sheets. The elements are produced by plywood, they are transported often 1000 miles (US) from the factory to the site. The elements are produced near the woods with attractive timber funds. The elements are made in structural point the same way for large luxurious houses 300 - 1000 sqm as for modest small houses 60 - 120 sqm. The element made by plywood construction has good stability, stiff and used to be well isolated. They can cut off on-site according to the wishes of the house buyer or renter.

At the southern part of Germany, people with high income chooses to build their own houses by new clay-brickwork. The clay-brickwork has good, acceptable isolating capacity, good damp status, high capacity to accumulate warmth energy. The thick wall gives a stabile feeling of security and space, but the type of construction is very expensive. The author of this article means; we can use our capital a better way as to build houses by old fashionable type, expensive constructions.

If we change in Sweden the production methods in housing, services and offices a. s. o. from on-site type of building methods to advanced prefabricated one, we can save 0,7% of the GNP. This change of the production apparatus can not happen at once in a short time, but it is desired in a longer perspective. The theoretical saving belongs to the low productions volume of 1995. During the late 1980-s high conjuncture we could save 2 % of the GNP.

Sweden belongs to the countries, where large part of the building production is prefabricated: normally between 7 - 15% of the total production. Countries with lower %-age of prefabricated production, in the future has the possibility to save more as Sweden does.

APPLYING THE ANALYSIS FOR DEVELOPING COUNTRIES - CONCLUSION

Nobel Laureate and professor of economics, Simon Kuznietz points out that industrial development and economic growth in industrialised countries and developing countries share certain basic features. The economic consequences of an effective industrial method based on new technology are equally favourable in industrialised and developing countries, We believe that the acute building needs of the developing countries should be satisfied by using more efficient methods: the slowly development of the building sector in industrialised countries must be avoided in the developing countries. By joint venture cooperations between i- and developing countries building companies' advanced building techniques and know-how has to be introduced in the d- countries, meeting the enormous needs of this part of the world.

Other economic studies as well show that the worth of the society lies in its knowledge of science and technology and not in its savings in worthy things as gold, brilliants, poetry, art etc. In d- countries we must build rapidly new dwellings. We do not have to give the houses high finish. Suitable rational and effective building methods must be given from the i- to the d-countries, and be adapted to the actual circumstances. Saving in finish and technical competence can give an additional up to 30% saving above mentioned savings. Some of the technicians doubts about this opinion, they emphasise that in the d-countries we can find unemployed no graduated working power, who can build by topic manual methods, "stones laid on stones" as we did it during the centuries. But our country Sweden shows to the world an other example in opposite politics. In 1850-s our country was poor. We had unemployment, need of hunger. We had emigration to USA in large scale. We could solve our necessary communications by more coachman's and horses. We had a lot of unemployed coachman's. They should be "much cheaper", that needed less of investments, that could occupy more people. I stead we choose for this time a very advanced railway system... and it gave results.

The author is convinced, effective building methods must be used in the developing-countries

We should not occupy people in an unproductive building industry. We have to invent the actual countries conditions and adapt advanced building methods to solve the needs. The finish of the building can be varied, but the structure for creating the room must be produced by a rational way.

The production of new buildings on world, which is relevant to this article, makes 7- 8% of the GNP. On the diagram 18 we can observe, the total production costs (landmark, sanitary supply, infrastructure, a. s. o., building-, projecting-, administrative- costs) can decrease 40%, if we choose instead of on-site-, prefabricated building methods. If we calculate that 50% of the production changes to prefab systems (i- and d- countries development is determinate to the metropolis areas) by 25% of saving we can save totally a. 1% of the GNP of the world. This is equal to the whole GNP of Sweden (plus eventually the GNP of Denmark).

Naturally the help to the self help has to be continued for the very poor people. The homeless, the unemployed have to do something for their own homes. They must self build their own homes. That is better if these people build their own homes, than do nothing. Acceptable conditions of the building materials, -road and exploration-supply (canalisation) a. s. o. must be fulfilled.

But the author of this article has on opinion; that the occupied, employed, medium income people of the developing-world must use the adopted, advanced building methods of the i- part of the world.

WHY IS THE POCESS OF RATIONALISATION IS SO SLOW IN BUILDING INDUSTRY?

The producers in building (constructors, owners, keepers, as well the community owned housing foundations) has limited interest to decrease the production costs; because they own the largest part of the building properties. A lower production cost results lower worth of the existing own properties, and opposite a higher production cost, if that can be financed, and later on rented or sold to consumers gives higher worth of the own volume of properties.

On the world we have a large stock of buildings which we have to take care of. Almost all of our old buildings maintains by original or similar to the original methods. Some case, by carelessness we use this old, conservative methods; when we build new units. The author of this document considers, it is very difficult to value the quality of environment against investments in money. Did the reader reflect any time, that the renovation of the residence of the prime minister of Sweden which contains 10 representative rooms costs so much as 150 two- tree bedrooms apartments? The building branch is very conservative. Did the reader of this side, meet a woman contractor?

The author of this article during his 40 years of working in the branch never met a woman building - contractor Why?

Administrative encumbrances, slow urban planning process, political power play and draw, the landowners and building companies ranger of districts, counteract collaboration and economical saves.

The building industry has short series; nevertheless avoids open building systems. Building industry is mainly home industry and in many countries constitutes like Sweden, as an employment and conjuncture balancing instrument, that contraries saving. In reality the building industry works with low degree of concurrence.

The companies are working on own landmark with equal production methods. So called "total economic solutions" means: to talk away real concurrent. Established methods persuades by the producers, accepts by the managers, who has dilemma about new methods and rather wish to increase the worth of the own properties with creative prize instrument (see above).

To change the production of housing to industrialised production is more motivated in high density regions. In our country, Sweden large territories has low density (less then 30 inhabitants./sqkm.. In spite of this, during 1970-s and 80-s in Göteborg has been constructed hospitals by elements of concrete prefabricated in Strömsund (distance: about 1200 km). Why? The middle sized companies has difficulties at an industrialised building market.

At the industrialised building construction the workers become new rolls: factory- and erection workers. That used to be protested by the unions.

The good quality of the production of buildings by prefabricated elements must be erected by new laws, as we have done it for "on-site" methods. But to modify the laws, erected for this type of building, takes time.

HOW CAN WE SAVE IN BUILDING ON EARTH AS THE WHOLE GROSS NATIONAL PRODUCT OF SWEDEN?

By computer technology the planners, the designers, producers record their products. The contractors buy one component of the house from one, the other from an other elements are produced within the actual building systems acceptant transport distance. Plates, sheets, and volume elements, picture 21, produces on effective way.

Picture 21

They are transported to the building site by trailers and lifted to their places in the building by cranes. The transport distance of the concrete elements can be up to 150 - 250 km, for wooden constructions 1000 - 1500 km.

We have to choice suitable places for factories within a district of production. In order to we have to take in consideration the sea- road- railway transport possibilities. We have to build "low and close" enclaves in maximum four- storey high buildings. The groups vary in different patterns, by this matter we get high degree of exploiting, which results relative low cost of supplies and good contact with the landmark, which gives human housing.

Our statement: move the least number of elements, and by this build the maximal number of rooms:

We mount the concrete elements in vertical forms (even volume elements), and by need in horizontally forms. The elements armed on tables by automatic welding.

The element are prepared to their functions of the building in the factory by finish. By this way we eliminate the work at the site. We vary the form of the rooms by placements of the doors, windows, cages in the form. We get rooms in different shape.

We build advantageously by box units, which contain vet rooms (bath, shower, kitchen, pool a. s. o.). The box units combines with each other and compete with plates and sheets, picture 22.

Picture 22

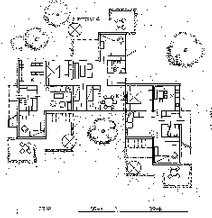

We can build apartment house accessed from the balconies, on picture 23 we see the section, on picture 24, 25, 26, 27 one- ,two-, three-, four-, bedrooms apartment. We build houses by box units combined with sheets, picture 28, 29.

Picture 23 Picture 24

Picture 25 Picture 26

Picture 27 Picture 28

Picture 29

On well planned buildings produced by prefabricated elements we can vary the elevations. On picture 30, we can see prefabricated houses, made by the same system, but designed in different way, from left to right: Swedish 1920-s, American high rise from 70-s, Post-modern oriental romantic of 90-s.

The theory of the production of architectural space is based on Swedish technical knowledge, Swedish salaries, Swedish investment costs and experiences. But that is valid to other countries. The working salaries used to be around 45 - 55% in the i- countries. In the s. c. "previous east block countries," in Central Europe, the working salary is 1/7-th part of the Swedish, the costs of the materials are 75% of the Swedish. In spite of that the total costs of the building are 75- 80% of the Swedish. This can be decelerated by considerable more "cheap" ineffective working hours in the previous eastern countries as in the western countries.

In the near future the wood and the wooden products will be lacking on earth. The timber needs for wooden products: for production of paper, interior works, furniture, a. s. o. The rests of the woods must be partially protected. Therefor we have to build more and more by silicates; first of all in concrete, but where we have lot of energy by lightweight concrete. The author of this article is sure about, that the chemists will find out new, not burning, light, silicate based materials, which can compensate or complete our daily building materials.

But for prefabricated buildings the relationship between the size of the elements, working times and -costs will be the same: that is based on the room- geometrical (architectural space) conditions.

The architectural space is grounded by the enclosing structure of the room (floor, walls, roof) and the form of the defined volume of the room (space within the enclosing construction). In future, as today the relationship follows the standard of the society, the level of working-, living-, capital- a. s. o. conditions and the physical conditions-, equipment's- of the house.

Summarising the content of this article, we state:

IF WE USE OUR KNOWLEDGE OF BUILDING AT UNCHANGED PRODUCTION OF NEW ROOMS:

IN SWEDEN WE CAN DECREASE THE INVESTMENTS COSTS BY 15%, AND

ON EARTH WE CAN SAVE MORE THAN THE WHOLE GNP OF SWEDEN

Information to the Swedish government 1970

Public in Zürich 1977.

Pictures: System Building,

Modern Architecture, Progressive Architecture.

Gebrauchmuster G 72334351.

Pattern 32796, 32696, 32500, 45154

Patent, pattern pendin

Copyright: Göran Ervin Schömer, Sweden.